Lubrication system dialysis cleaning machine lubrication system maintenance

- group name

- Engine Flush Machine

- Min Order

- 1 piece

- brand name

- Zeayeto

- model

- LS-302

- Nearest port for product export

- Shenzhen, HongKong

- Delivery clauses under the trade mode

- FOB, CIF, EXW

- Acceptable payment methods

- T/T, L/C, Credit Card, Westem Union, Cash

- update time

- Wed, 20 Mar 2019 15:14:53 GMT

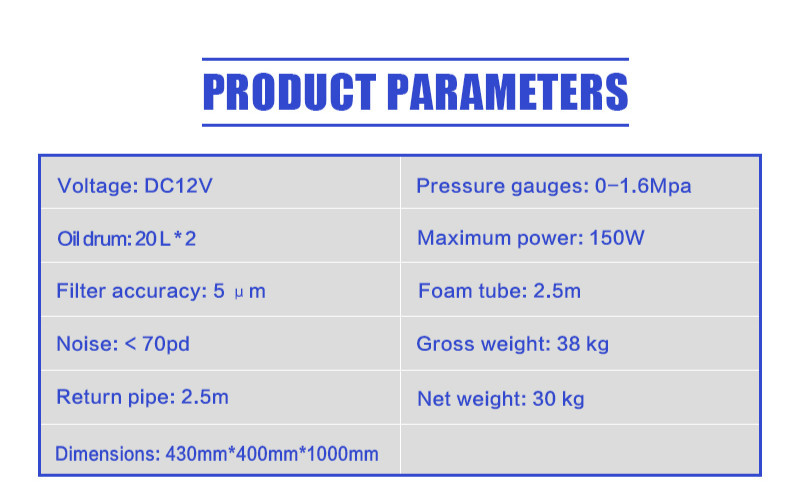

Paramtents

Color grey

Voltage DC12V

Power 150W

Filter accuracy 5 µm

Working noise <70db

The tubing 2*2.5m

Weight 40kg

Size 430mm*400mm*1000mm

Packging & Delivery

- 43cm x40cm x100cm

-

Min Order1 piece

Briefing

Detailed

Lubrication system dialysis cleaning machine lubrication system maintenance.

This equipment adopts all-intelligent computer board to control the whole process of cleaning. The whole cleaning process is controlled by one button. After setting the parameters, it only needs one person to be on duty, and the operation is simple and safe. The most safe cleaning of the lubricating oil passage in the form of static cleaning, which is a good assistant for deep maintenance of the engine.

If you have any questions, please CONTACT US

The main function:

1.Add new oil

2.Oil recovery

3.Automatic operation mode

4.Circulation cleaning

5.Time can be adjusted according to actual situation

If you have any questions, please CONTACT US

Summary of the equipment:

This equipment adopts the whole intelligent computer semi-control to clean the national production, the whole cleaning process one-key intelligent control, the operations simple and safe. The most safe way to clean the oil passage ia to use cleaning.

Product features

1. Double display window, easy to observe the effect of oil change and customer marketing.

2. Use high precision cotton filter to ensure clear effect.

3. One-key intelligent cleaning, oil change, easy operation, labor saving, simple training.

4. Special customized quick connector, the first in the industry, long service life of high-end quality.

5. The time of filling, cleaning and pimping can be set independently.

Why choose us

1. Good quality, preferential price

We adhere to the principle of quality first and provide customers with quality products.

2. Ten years of technology precipitation, trustworthy

We focus on the development and production of automatic transmission oil changers, which have been continuously created and continuously improved over the past decade.

3. Quality service

Profession pr-sales and after-sales service team, customer-centric, to provide you with peace of mind, heartfelt service.

If you still have questions, please click: Please Enter